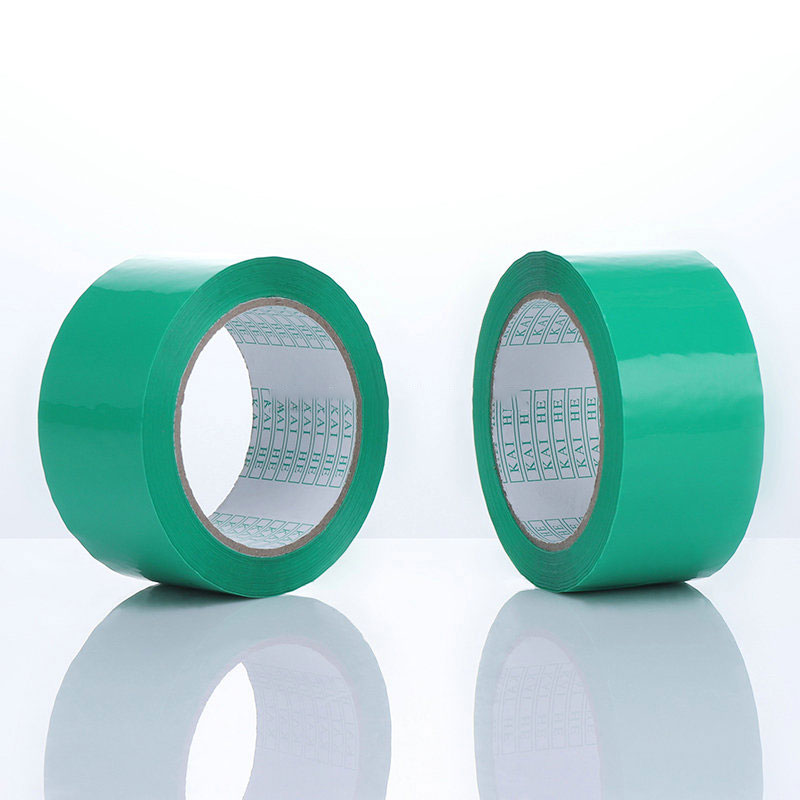

specializing in the production of stretch film, adhesive tape, packing tape, etc

Single-Side Bopp Adhesive Tape vs Other Types of Adhesive Tape?

Single-Side Bopp Adhesive tape consists of Biaxially Oriented Polypropylene (BOPP) film with an acrylic, rubber or hot melt adhesive coating on one side. It is commonly used for packaging and sealing applications in different industries.

Depending on the adhesive coating, adhesive cure technology and backing, tapes perform differently. This includes tensile strength, peel strength and temperature resistance.

The most common types of adhesive tape are pressure-sensitive tapes and double-sided tapes. Pressure-sensitive tapes are tacky at room temperature in dry form and will adhere to a variety of surfaces, including paper, plastic, glass, wood, cement and metal without water, solvent or heat activation.

Other types of adhesive tape are thermally activated, requiring moisture or a solvent to work and include latex gums. They may also be coated on both sides with an acrylic or rubber adhesive, but are typically thinner and less durable than the pressure-sensitive tapes.

The most important quality to look for in an adhesive tape is tensile strength and shear force resistance. This is critical to ensure that the tape will be able to withstand the stresses it will experience in use.

英语

英语 日语

日语 西班牙语

西班牙语 阿拉伯语

阿拉伯语

.jpg)